(un)woven.

Designing with unrecyclable textile fibres.

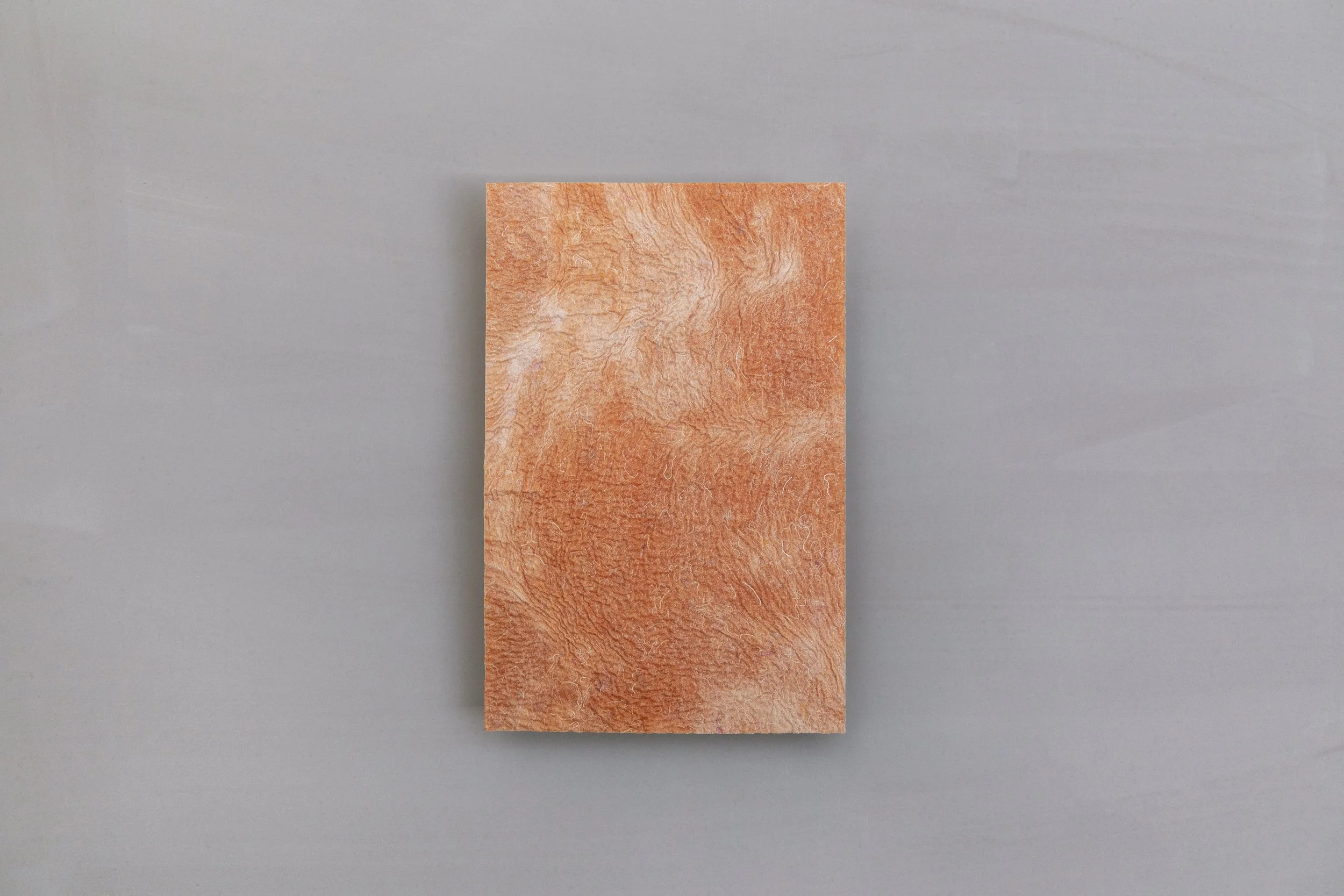

From marble-like patterns to developing novel dyeing processes using natural pigments for mixed blend unrecyclable textile fibres. A unique production method turns inferior mixed blends into an architectural biotextile for interior and product design applications.

(un)woven, previously known as Pre-Loved, is a new bio-textile concept made of inferior textile fibres, created as an alternative to the flawed traditional textile recycling process. A unique production method turns inferior mixed blends into a lightweight biotextile suitable interior and product design applications. Emphasising recyclability over longevity, the sturdy material can be recycled at the end of its life and repurposed for new production cycles over and over again.

All tones at a glance

Frequently asked questions:

-

(un)woven is a non-woven made of various types of post-consumer or post-industrial fibres. The biodegradable binding process developed by Studio Sarmīte (patent pending) gives the final material suede strength and paper-like texture

-

(un)woven does not aim to replace leather. It is an entirely different material with new and unique properties. It reflects the look of paper, yet feels like textile

(un)woven can be used for a wide range of applications that require a sturdy textile-like material. We recommend applications such as wallpapers, panels and decorative surfaces.

The material can be glued, stapled or nailed.

(un)woven is biodegradable and as such it should not be washed. Dust and dirt can be cleaned off with damp cloth.

-

(un)woven is produced in sheets, length and thickness of sheets are customisable to order specifications

Lead time is 6-8 weeks

We are happy to collaborate, customise and R&D on individual basis

-

- Yes, it is fully circular. We value circularity over plain longevity. That is why we use a natural and biodegradable glue that ensures the biotextile can be recycled again at the end of its life.

How does this work: We are able to recycle fibres endlessly as our process sets no limit to fibre length, we can even process textile dust.

Custom biotextile Wall Panelling | Private residence

Custom biotextile Wall Panelling | Private residence

Custom biotextile Acoustic Panel & WallArt | Private residence

Custom biotextile WallArt | Private residence

TransLucent recylced denim | Detail view

(un)woven x Gateris Works for Molberts | TransLucent recycled denim biotextile

TransLucent recycled denim Space Dividers | “Icons Re/Outfitted” exhibition

TransLucent recycled denim Space Dividers | “Icons Re/Outfitted” exhibition

Redesigned Panton Chair | “Icons Re/Outfitted” exhibition

Detail view | “Icons Re/Outfitted” exhibition

(un)woven wall panels

(un)woven wall panels l detail

(un)woven wall panels l detail

(un)woven seat

(un)woven seat

(un)woven seat l detail

(un)woven x Been London

(un)woven x Been London

Interested in more?

For more information, media coverage and requests, please visit the (un)woven website www.unwoven.studio